Product Description:

The Polyol and Isocyanate product is a high-quality blend designed specifically for the production of polyurethane foam. This product combines carefully formulated polyol and isocyanate components to deliver exceptional performance in various applications, most notably in the manufacturing of rigid foam. The blend polyol and isocyanate system is engineered to react efficiently, producing polyurethane foams with excellent mechanical properties and superior insulation capabilities.

One of the key features of this product is its incorporation of a Cyclopentane blowing agent, which significantly enhances the foam's cellular structure. Cyclopentane is recognized for its environmentally friendly profile and excellent blowing characteristics, contributing to the formation of foam with approximately 90% closed cells. This high closed-cell content is crucial for applications requiring outstanding thermal insulation and structural integrity, making the rigid foam produced with this blend ideal for use in construction, refrigeration, and other insulation-related industries.

The Polyol and Isocyanate product is classified as DG (Dangerous Goods), which means it requires careful handling and storage following safety regulations. Despite this classification, the product is formulated to be stable under recommended storage conditions, ensuring consistent quality and performance throughout its shelf life. Stability is a critical factor in maintaining the reactivity balance between polyol and isocyanate, which directly affects the foam's physical properties such as density, compressive strength, and dimensional stability.

Our blend polyol and isocyanate system supports the production of rigid foam with excellent dimensional stability and durability. The 90% closed-cell structure achieved through the use of the Cyclopentane blowing agent imparts superior resistance to moisture absorption and thermal conductivity, making the foam an ideal choice for energy-efficient insulation. This contributes to reduced energy consumption and improved environmental sustainability in buildings and appliances where the foam is applied.

In addition to its outstanding material properties, this product is backed by comprehensive technical support from our experienced team. We understand that successful polyurethane foam production requires precise control over formulation and processing parameters. Therefore, we offer expert guidance and troubleshooting assistance to help manufacturers optimize their production lines, achieve consistent foam quality, and meet stringent industry standards. Our technical support covers formulation advice, processing techniques, safety protocols, and environmental compliance, ensuring that customers gain maximum value from the Polyol and Isocyanate product.

Whether used in the fabrication of insulation panels, refrigeration units, or other rigid foam applications, this blend of polyol and isocyanate delivers reliable performance and enhanced foam characteristics. The combination of stable chemical components, environmentally friendly Cyclopentane blowing agent, and a high closed-cell content results in polyurethane foams that meet the demands of modern construction and industrial needs. Its application versatility and strong technical support make it an excellent choice for manufacturers aiming to produce high-quality rigid foam products.

In summary, the Polyol and Isocyanate product is a stable, DG-classified blend tailored for the efficient production of rigid polyurethane foam with superior insulation properties. The use of Cyclopentane blowing agent ensures a foam structure with approximately 90% closed cells, contributing to excellent thermal performance and durability. Supported by our dedicated technical team, this product offers a comprehensive solution for manufacturers seeking to optimize their polyurethane foam production processes and deliver premium insulation materials to the market.

Technical Parameters:

|

Stability

|

Stable

|

|

Technical Support

|

We Can Provide Technical Support

|

|

Application

|

Polyurethane Foam Production (Rigid foam with Cyclopentane Blowing agent, 90% closed cell)

|

|

DG Or Non

|

DG

|

|

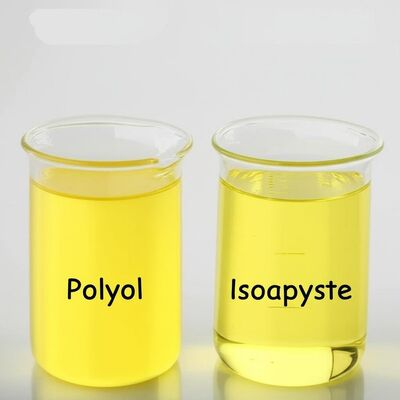

Appearance

|

Light Yellow Liquid

|

|

Materials

|

Blend Polyol & Isocyanate

|

Applications:

The Joyway Polyol and Isocyanate product, originating from China, is a high-quality blend designed specifically for polyurethane foam production. This light yellow liquid formulation combines advanced polyol and isocyanate materials to deliver outstanding performance in creating rigid foam with approximately 90% closed cell structure. Such a composition ensures superior insulation, durability, and mechanical strength, making it an excellent choice for various applications.

This product is widely used in the manufacturing of rigid foam panels, which are essential in construction, refrigeration, and packaging industries. The rigid foam produced with Joyway’s polyol and isocyanate blend provides excellent thermal insulation, reducing energy consumption in buildings and refrigeration units. Its high closed cell content enhances moisture resistance, making it ideal for environments requiring long-lasting insulation properties.

In addition to construction and refrigeration, the Joyway Polyol and Isocyanate product is suitable for producing rigid foam components in automotive and marine industries. The rigid foam’s lightweight yet robust nature helps improve fuel efficiency and structural integrity in vehicles and boats. Moreover, its versatility allows for customization in foam density and rigidity, catering to specific application needs.

Joyway’s commitment to quality is backed by comprehensive technical support, ensuring that manufacturers can optimize the use of this product for their unique production processes. Whether you are developing insulation panels, structural foam parts, or specialty foam products, the technical team at Joyway can provide expert guidance to achieve the best results.

It is important to note that the product is classified as DG (Dangerous Goods) due to its chemical nature, requiring careful handling and compliance with safety regulations during transportation and storage. With proper precautions, the Joyway Polyol and Isocyanate blend is a reliable and efficient solution for producing high-performance rigid foam with 90% closed cell content, enhancing the quality and longevity of polyurethane foam applications across various industries.

Support and Services:

Our Polyol and Isocyanate products are backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide expert guidance on product selection, formulation advice, and processing techniques tailored to your specific applications. Our technical team is available to assist with troubleshooting, quality control, and to offer solutions that enhance product efficiency and durability. Additionally, we offer training sessions and detailed documentation to help you maximize the benefits of our Polyol and Isocyanate products. Commitment to excellence and customer support is at the core of our service offering, ensuring you receive the best possible assistance throughout your product lifecycle.

Packing and Shipping:

Product Packaging and Shipping for Polyol and Isocyanate

The Polyol and Isocyanate products are carefully packaged to ensure safety and quality during transportation. Polyol is typically packaged in steel drums or intermediate bulk containers (IBCs) with secure sealing to prevent contamination and leakage. Isocyanate is packaged in airtight, moisture-resistant containers such as metal drums or specialized IBCs to maintain product integrity and prevent exposure to moisture.

Both products are clearly labeled with handling instructions, hazard warnings, and product information in compliance with international shipping regulations.

For shipping, Polyol and Isocyanate are transported separately under controlled conditions to avoid any risk of reaction. Shipping methods include road, sea, or air freight, depending on the destination and urgency. Proper documentation accompanies each shipment to ensure compliance with safety and environmental standards.

During loading and unloading, care is taken to handle containers gently and store them in a cool, dry place away from direct sunlight and incompatible materials. Emergency response information is provided to handlers to address any accidental spills or leaks promptly.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!